SPECIAL ACCESSORIES

DESIGN AND PRODUCTION OF SPECIAL ACCESSORIES FOR INDUSTRIAL MACHINERY

The HMI offer also includes the development and production of special accessories for machinery, either supplied individually or developed and installed directly on the machine.

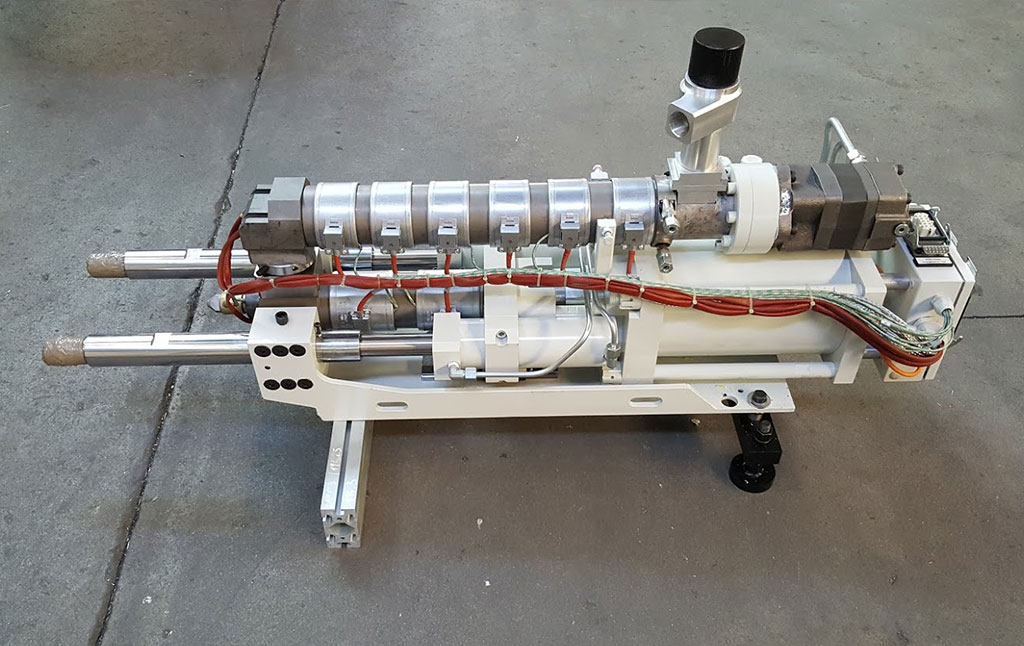

INJECTORS

| Injection volume | cc | 460 |

| Specific pressure bar | bar | 1600 |

| Total injection unit length | mm | 1045 |

| Injection carriage feed column spacing | mm | 210 |

| Total injection unit height | mm | 580 |

| Injection point height from the base | mm | 145 |

| Injection unit stroke | mm | 110 |

| Injection point height from the base | Mm/sec | 100 |

| Heating power | kw | 7,8 |

POWER UNITS

THERMOREGULATION OF HOT RUNNER SYSTEMS

- Up to 256 temperature control zones

- Modularity 8-12-16 areas

- Wiring on standard or customer-specific 16amp harting sockets • self-adaptive P.I.D.

- Thermocouple faulty or reversed signal

- Reporting of resistance failure

- Monitoring and reporting of energy anomalies

- Preheating function with measurement of the dissipation towards the ground and temporary self-exclusion of the resistance in dissipative anomaly • Automatic reset of the resistors with dissipative anomaly solved

- • Automatic census of connected resistors identifying the total number of active channels, electrical power measurement of each resistive element applied and ohmic value measurement of each resistive element applied

- Logical grouping into distinct element families (nozzles and hot runners)

- Temperature setting for single zone or logic group REPORT and CYCLE ANALYSIS

- Synchronisation with the press cycle

- Measurement, monitoring and storage of machine cycle time • Measurement, monitoring and storage of injection pressure • Measurement, monitoring and storage of injection speed

- Quality report with weighted graphs and averages of temperature, pressure, speed, and position

PREFORM MACHINES