REVAMPING / RETROFITTING

REVAMPING AND RETROFITTING INTERVENTIONS ON OBSOLETE MACHINERY

The HMI internal team is directly responsible for revamping and retrofitting activities for updating and adapting the obsolete machinery. Thanks to the synergistic skills of the operators, HMI carries out interventions for the total, partial revamping and retrofitting of the electronic components, ensuring the customer the restoration of functionality, greater efficiency of the machinery, a better energy production ratio and compliance with current regulations in terms of safety and performance.

MACHINERY REVAMPING OPERATIONS

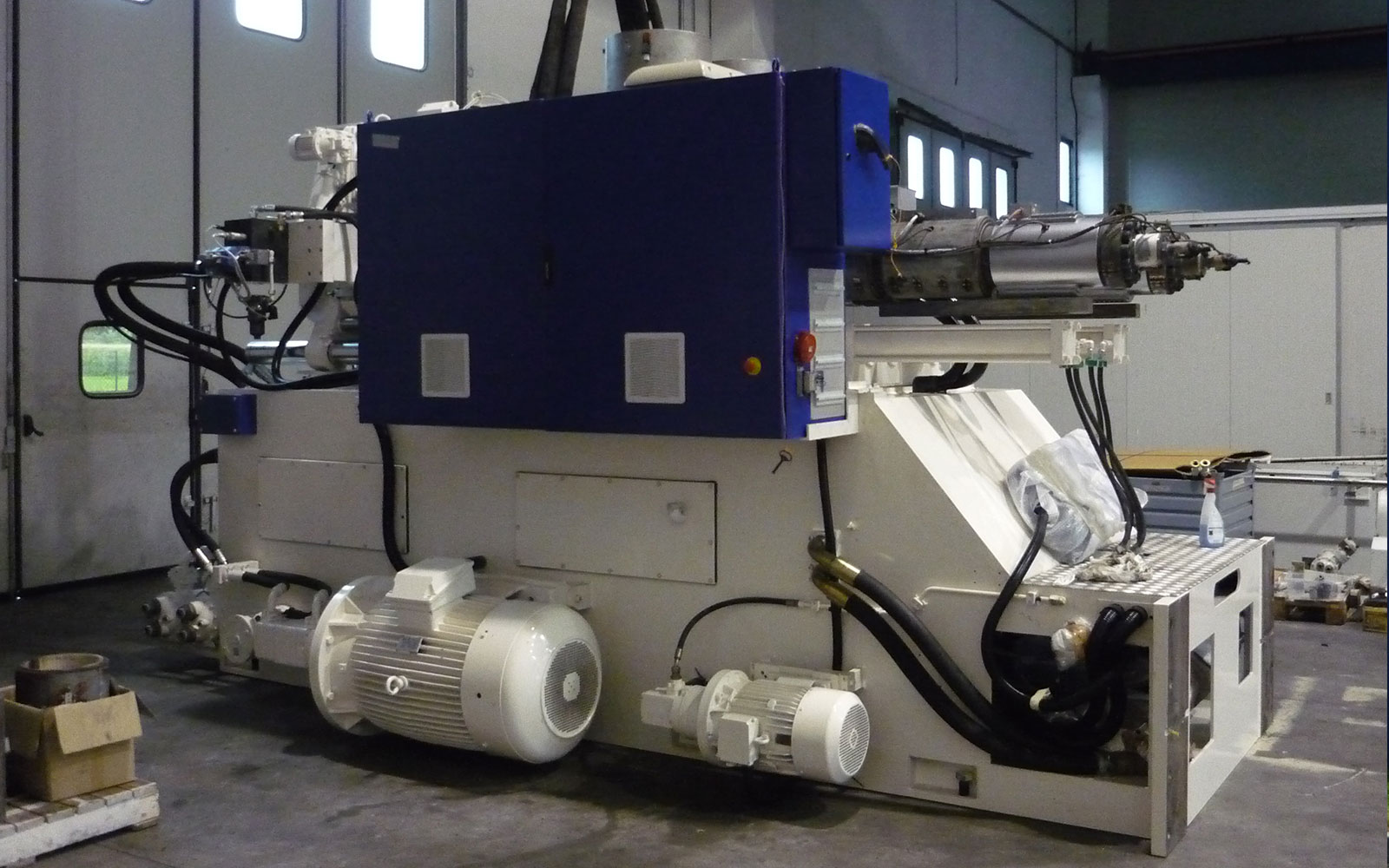

HMI carries out machine and plant upgrading, including dismantling internal and external parts, checking functionality, and making mechanical and structural modifications.

By replacing outdated components, worn parts, internal and external cleaning and installation of new, up-to-date equipment, machinery not only obtains new high efficiency and performance but can also be modified to meet new production requirements.

![]()

![]()

![]()

RETROFITTING OF INDUSTRIAL MACHINERY

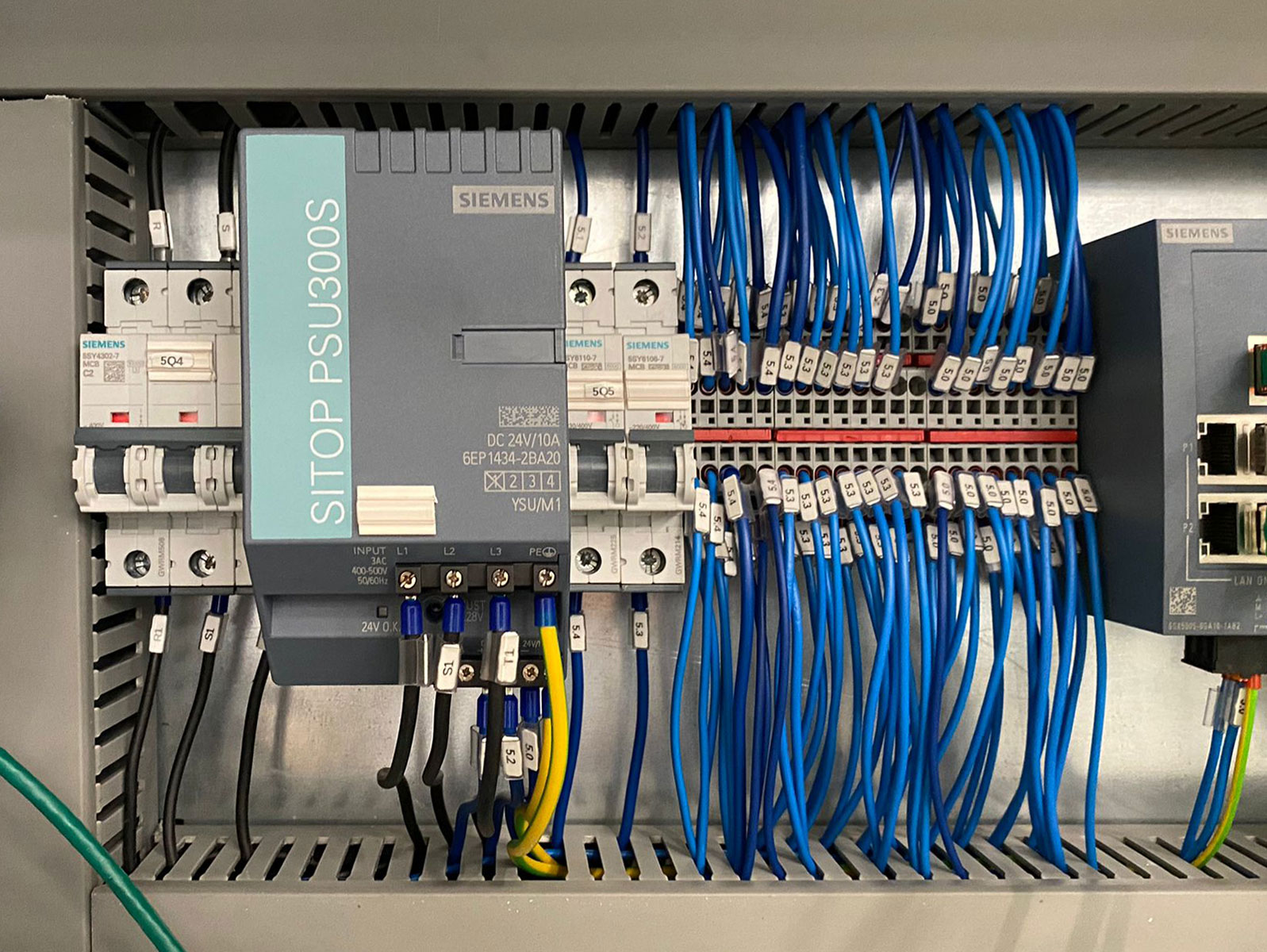

With the retrofitting of hydraulic presses, HMI installs up-to-date technological components to replace obsolete electrical and electronic parts, thus making the machinery perfectly efficient and reducing its energy impact.

Among the activities carried out, we mention:

- Installation of high efficiency inverter or servo pump

- High-resolution position sensors

- Ergonomic keyboard console

- Direct control of hot runner systems

- Closed loop pressure profiles

- Rolling plan position profiles controlled in closed loop speed and pressure

- Adaptation to current safety regulations